Steam biocleaning: The hygienic solution for the Food Industry

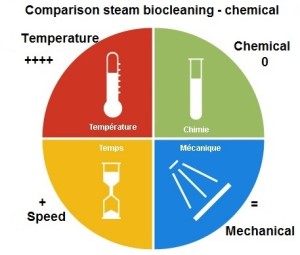

Steam biocleaning is particularly interesting for the Food Industry thanks to its high cleaning and disinfecting efficacy combined with the non utilization of chemical product and very low water consumption.

High temperature (150°C) and high pressure (5 bars) steam provides infallible cleaning power.

The steam obtained, called neutral due to the absence of any mineral and devoid of any electrical conductivity, neutralizes static charges of dust formations. The steam acts as a gaseous substance. Its heat melts fats and eliminates all grime and filth.

Steam can easily access even the most inaccessible corners in order to eliminate dirt for a simpler, more efficient and lasting clean.

Steam eliminates dirt deposits and biofilms and allows for an excellent reconditioning of surfaces.

The use of microfibers with the accessories ensures a perfect elimination of all grime. Another possibility is to use a vacuum-cleaning device to ensure elimination of grime.

Efficiency: Disinfection

The strong biocide action of the temperature of the steam also ensures excellent disinfection results that conform to European norms NF EN 14561: 2007, NF EN 15562: 2006, NF EN 14563: 2004 and norm NF T72- 281.

- Bactericide > 5 logs reduction

- Mycobactericide > 4 logs reduction

- Virucide > 4 logs reduction

- Yeasticide > 4 logs reduction

- Sporicide > 3 logs reduction (Steam combined with 7.5 hydrogen peroxide solution)

The efficiency of SANIVAP’s steam cleaning method is recommended, published, and has undergone numerous verifications in laboratories and in-situ.

Simplicity and speed

The effect of the steam allows the detergence and disinfection of surfaces in one use. This combination saves time and increases the simplicity of biocleaning processes.

The steam cleaning method also reduces the frequency of certain cleaning tasks as surfaces dirty at a slower rate due to the steam cleaning.

Cleaning staff becomes more efficient and motivated since the task becomes easier and fulfilling.

Economy

Since no detergent nor disinfecting product is needed, significant savings are expected on operating budgets. Water consumption is also greatly reduced. Studies demonstrating significant economical gain have been carried out by users.

Respecting the environment

The SANIVAP steam cleaning method meets the objectives of sustainable development. : no chemical, reduced water consumption, no polluting emissions. It is a method that is 100% eco-friendly.